Status of marine co-products in Portugal: overview, opportunities, and challenges

“One man’s trash is another man’s treasure” – Proverb

Marine co-products: a long pathway to be valued

In the last years, we have been witnessing a change in mentality and politics regarding the introduction of good practices in order to redesign, reuse and recycle materials that aim to enhance sustainability, circular economy and avoid food waste. Terms like garbage, waste, residue and most recently by-product were, for many years, used to describe food that was discarded or applied for other purposes other than the food chain. With a wide range of new applications for these raw materials and their value increasing, these terms quickly changed in order to end with the pejorative connotation that they carry. It was in this paradigm that the concept of co-product in the food sector emerged.

According to the Business Dictionary, co-product is a term that can be defined as a “product manufactured along with a different product, in a process in which both are required in the production of another product. In comparison, a by-product is usually an undesirable product”. In chemistry, for example, co-product is a substance formed at the same time as the main or desired product during a chemical reaction that has equal or comparable economic significance (e.g., in mining and extraction of ores, many of the elements recovered are of similar economic significance to one another) [1]. The difference to a by-product focuses essentially on a material that is incidental to the production process of other products, and it is negatively rated due to not being a primary product. Often the companies that generate the co-products know of no ways to value them, labelling them as waste, instantly lowering its market value.

Like other food sectors, fisheries, aquacultures, seafood processing industries and other marine-derived food sectors generate large amounts of co-products in their processes. These raw materials, i.e., marine co-products, include fish, crustaceans, and molluscs, but also other aquatic species, like aquatic mammals, reptiles, sponges or seaweeds that are now used for other reasons than food or feed. In fact, today we find a wide range of industry applications, from chemical industry to medicine, pharmaceutical, biofuel, biogas, clothing, plastic, or biomedical devices and even jewellery, among others [2].

Despite this enormous potential of marine co-products there are still a lot of challenges related to legal barriers, industry awareness and technologies in order to extract all the capacity of these precious and abundant raw materials.

Worldwide overview of marine co-products

The most recent data from FAO shows that about 88% (156 million tonnes) of world seafood production in 2018 was utilized for direct human consumption and the remaining 12% (22 million tonnes) was used for non-food purposes, mainly to produce fishmeal and fish oil. Both can be produced from whole fish, fish trimmings or other fish processing co-products, and are still considered the most nutritious and most digestible ingredients for farmed fish, as well as the major source of long chain omega-3 fatty acids (eicosapentaenoic acid [EPA] and docosahexaenoic acid [DHA]) [2]. Despite fish oil representing the richest available source of long-chain polyunsaturated fatty acids (PUFAs), which performs a wide range of critical functions for human health, The Marine Ingredients Organisation (IFFO) estimates that about 75% of annual fish-oil production is used in aquaculture feeds [3]. Co-products can also be used to produced fish silage, obtained through acidification and natural protein hydrolysis, which is a rich protein hydrolysate and a less expensive alternative to fishmeal and fish oil. It is increasingly being used as a feed additive, for example, in aquaculture and in the pet-food industry, since it has the potential to improve growth and reduce mortality of fed animals [4] [5].

Since direct human consumption of fish is increasing at an average annual rate of 3.1 % (from 1961 to 2017) it is expected that seafood co-products continue to increase. On the other hand, a demand driven by a fast-growing aquaculture industry (which already represents 46 % of the total production), has been increasing the prices of fishmeal and fish oil. As a result, a growing share of fishmeal and fish oil has been produced from fish co-products. Currently, these co-products, which previously were often discarded or used as direct feed, in silage or in fertilizers, are estimated to represent up to 25–35% of the total volume of fishmeal and fish oil. Additionally, the growth of fish processing industries in recent years has resulted in increasing quantities of co-products, which may represent up to 70 % of processed fish [2].

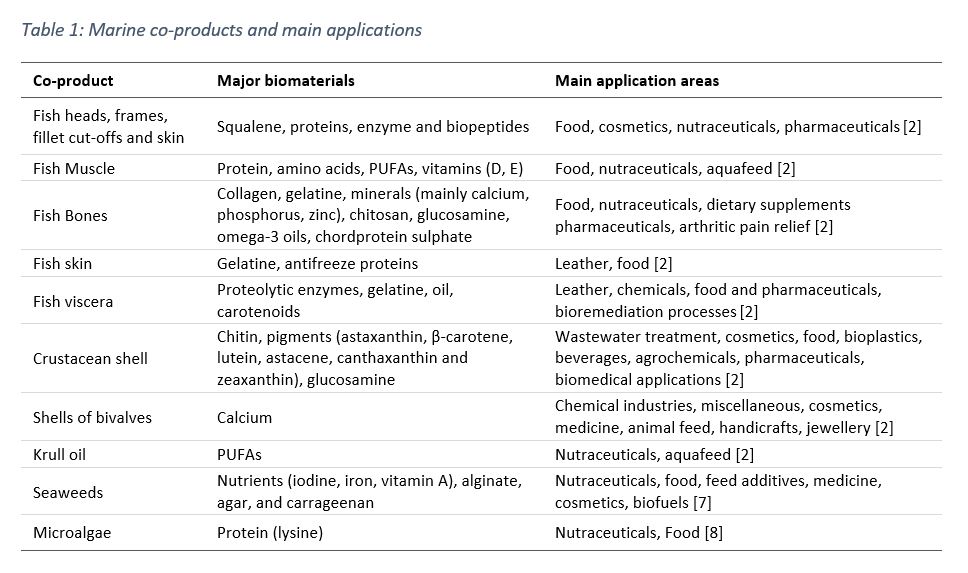

Regarding animal co-products, in which marine co-products are included, the EU establishes specific legislation (Regulation EC 1774/2002) laying down strict animal health and public health rules applicable to the protection, transport, storage, handling, transformation and use or disposal of this type of co-product. Canned and processed seafood industry generate large amounts of co-products, and most are recovered in line with these directives (Category 3, i.e., safe co-products that can be reintroduced in the food chain), being often used to produce fish meal and oil, which while profitable is not the highest value application available. Fish co-products are usually composed of heads (9–12% of total fish weight), viscera (12–18%), bones (9–15%), scales (about 5%) and skin (1-3%) that have many profitable applications [6]. Seaweeds, aquatic plants and other aquatic organisms are also the subject of promising research and pilot projects for application in medicine, cosmetics, water treatment, food industry, and biofuels. Some of the main applications are described in Table 1:

Circular economy as a key to avoid environmental impact

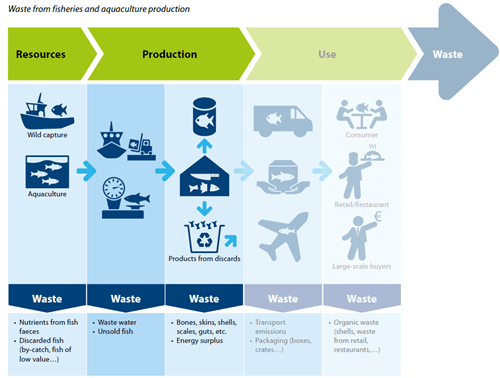

The increase in overexploited fish stocks is one of the indicators, but not the only, that the state of the world’s marine fisheries is deteriorating, with a negative impact on seafood production at both economic and social levels. Discards are a waste of biological resources, being partly responsible for the depletion of populations of aquatic species. Co-products can be originated in ports and auctions where the first sale of seafood takes place, in seafood processing industries (e.g., canning, seafood freezing, salting and drying industries of cod), in trawl fleets (non-target species), and on-board processing (evisceration and subsequent cleaning – sometimes around 80% of the individual). This evisceration on board contributes, in addition to the adverse effects on the food chain, to the accumulation of pollutants such as PCBs, dioxins and heavy metals and the dispersion, in fishing areas, of parasites existing in the viscera. To avoid this, the European Commission has taken several actions to implement “zero-waste” and “no discards” policies, thus highlighting the importance of valuing marine co-products as a measure to reduce waste. Furthermore, the European Action Plan for Circular Economy includes a set of related initiatives for the establishment of a strategic framework for the sustainability of products, including circularity in product processes [12].

In this scenario, biological resources are a key input to the EU economy and will play an even more important role in the future, since the development of blue bioeconomy based on marine bioresources has been considered fundamental to meet the growing need for raw materials. The use and enhancement of these bioresources allows for the diversification of raw materials, reduces the pressure on natural resources, and thus contributes to the preservation of the environment and the mitigation of climate change consequences. Thus, it is fundamental to develop biorefinery and circular economy concepts, changing attitudes towards waste from production processes and rethinking co-products’ complete valorisation, reduce losses [4].

Blue Bioeconomy in Portugal: an ocean of opportunities and challenges

Portugal stands out among the EU countries for its peripheral location and for its vast exclusive economic zone , and a fisheries sector with relevant economic activity. According to the National Institute of Statistics, national aquaculture production in 2019 was 14 337 tonnes and generated revenue of 118 529 €, which reflected increases of near 2.5% in quantity and 22.4 % in value compared to 2018). Regarding fish catches, they reached 163 837 tonnes in 2020 (13,1% less than 2019) reversing the upward direction that occurred in previous years and that is due to the COVID-19 pandemic [9].

Given the importance of the sea for Portuguese economy, Portuguese and European political agendas have been prioritizing the Blue Bioeconomy sector as one of the economy sectors with greatest growth potential. Since Expo 98, dedicated to the oceans and the future, and the Boosting Program for Marine Sciences and Technologies, created at that time, Portugal has multiplied the number of researchers in marine sciences, created highly equipped laboratories and research units and integrated these assets in European science networks. Between the most recent funding programmes, MAR 2020 and Fundo Azul stand out, as well as multiple European funding mechanisms covering marine-related activities in the past years. The valorisation of marine co-products is one of the topics that these programs hope to exploit and leverage. In this context, several activities and projects have been developed, most of them internationally, but also some interesting national initiatives.

Within the scope of marine co-products mapping, projects NEPTUNUS and ENABLING stand out. The first aims to create a seafood waste stakeholder’s platform with the involvement of all seafood chain actors and Atlantic countries, and the second developed a European biomass trade platform to join producers and processors, to exchange currently not valorised organic co-products. In last years, some Portuguese projects were developed for the valorisation of marine co-products via development of new strategies to create new formulations for food or feed, but also cosmetics and/or biomedicine applications. These developments included the creation of new processing technologies or biorefineries. Examples of projects include ICOD, NOVOMAR, MULTIBIOREFINERY, VALORINTEGRADOR and VALORPEIXE. VALORMAR is the most recent national project that intends to add value to marine resources for different applications, through the development of new technologies and biorefinery processes. Also of note is CONSERVAL, an Interreg cooperation project between Portugal and the region of Galicia (Spain) to develop technologies for the recovery of co-products and wastewater from the seafood canning sector. Considering that Spain is the major producer and exporter of canned seafood in the EU and Portugal is the fourth, this project is highly relevant to understand the real situation of this sector. A survey carried out by this project shows that most companies inquired generate category 3 co-products from processed seafood (300 to more 4 200 tonnes/year), with an estimated 30 – 70% discarded as solid waste (heads, viscera, tails, bones, etc.). The same study reveals that 47% of the seafood canned in Portugal are tuna, 19% sardines, 19% mackerel and 15% other species.

More recently, in 2020, BLUEBIO ALLIANCE, in association with CIIMAR, published the Blue Bioeconomy Roadmap for Portugal [10]. The report explored the economic sectors of Blue Bioeconomy and collected data about bioresources and their application in Portugal. Main results show that Portuguese Blue Bioeconomy stakeholders focus on seafood as a resource (37%) and food as destination (47%). Nevertheless, other resources and applications are gaining considerable attention: 17% of the actors use marine bacteria, 16% microalgae and 15% macroalgae. Also, 19% of the actors work with pharma, 18% with cosmetics and 18% with feed and nutraceuticals industries. Despite the enormous potential of co-products, only 8% use co-products from the seafood industry.

In Portugal there are some companies recycling and transforming marine co-products. SAVINOR UTS (from Soja de Portugal’s Group) is the major company in the sector, collecting, treating, and recovering all seafood co-products from the canning industries in Portugal and Galicia, transforming them into sustainable fishmeal and fish oil. ETSA Group in Lisbon and Figueirense de Pesca in Figueira da Foz are other important players in Portugal.

Regarding algae, research and development, as well as industrial activities are growing in Portugal, with a number of actors leading the way, namely, A4F, Algaplus, AllMicroalgae, Necton, Iberagar and Buggypower. However, the production of algae in Portugal is still small and it is not yet known if it generates co-products. [11].

Despite the acknowledgment of marine co-products’ great potential, there are still numerous challenges and barriers that hinder the progress to foster its valorisation and reduce food waste. Some co-products may not be produced in sufficient quantities to allow for the scale-up of added-value uses. There is still lack of accurate information about the quantities produced and composition of co-products from seafood processing industries. Even with new technological developments during the last years developed by researchers, there are some barriers for their implementation in the industry. Many companies do not even know what their co-products potential is, nor have sufficiently organized markets for these co-products and even less for biotechnological applications. Also, there is resistance to change processes inside organisations because it implies costs, employees’ training, new separation and segregation processes, logistics and food safety issues. In addition, there are challenges related to limited knowledge-transfer and correct communication between the industries that hold the know-how and Academia that could promote innovation or research to overcome difficulties. Finally, the valorisation of co-products has always legal and regulatory implications, that are bureaucratic and sometimes confusing due to differences between European and Portuguese, resulting in delays in the implementation of these innovative processes.

What B2E is working on related to marine co-products

Our team operates as an innovation facilitator key agent bringing innovative ideas into maturation and higher valorisation levels across different markets, while improving communication between Academia and Industry, therefore stimulating relationships between these sectors. B2E is strategically positioned to accelerate the sustainable development of the Portuguese Blue Bioeconomy, specifically acting in the marine biotechnology area, as well as aquaculture and valorisation of marine living resources.

We are currently developing a project to map marine co-products in Portugal. With this project, we will build the biggest data base concerning this segment, fostering and multiplying participants’ consortium options as well as profitable services. To do so, B2E intends to collect detailed information about types and quantities of these co-products, serving as the basis for the creation of a toolbox for identification of new value chains.

Our activity is leveraged not only by a team of multiskilled collaborators, but also by an invaluable network of associates that strategically cover the entire value chain of B2E’s operating areas – this fruitful interaction with our associates has been successful in propelling us into the spotlight and B2E’s name is starting to gain some traction. So, if you work in these subject and would like to boost your business, talk to us!

References

[1] A Dictionary of Chemical Engineering., Science and technology, Engineering and Technology, 2014.

[2] FAO, “The State of World Fisheries and Aquaculture 2020,” Sustainability in action, Rome, 2020.

[3] Auchterlonie, N., “The continuing importance of fishmeal and fish oil in aquafeeds,” in Aquafarm, Pordenone, Italy, 15–16 February – 2018.

[4] Kim, S.-E. & Mendis, E., “Bioactive compounds from marine processing byproducts – a review,” Food Research International,, vol. 39, p. 383–393, 2006.

[5] Toppe, J., Olsen, R.L., Peñarubia, O.R. & James, D.G., “Production and utilization of fish silage. A manual on how to turn fish waste into profit and a valuable feed ingredient or fertilizer.,” FAO, Rome, 30 pp., 2018.

[6] Al Khawli, F., Pateiro, M., Domínguez, R., Lorenzo, J.M., Gullón, P., Kousoulaki, K., Ferrer, E., Berrada, H. & Barba, F.J., “Innovative green technologies of intensification for valorization of seafood and their by-products.,” Marine Drugs,, vol. 17, p. 689, 2019.

[7] Tanna, B. & Mishra, A., “Nutraceutical potential of seaweed polysaccharides: structure, bioactivity, safety, and toxicity,” Compreensive Reviews in Food Science and Food Safet, vol. 18(3), no. 817–831, 18(3): 817–831. 2019.

[8] E. Álvarez-Castillo, M. Felix, C. Bengoechea, and A. Guerrero, “Proteins from agri-food industrial biowastes or co-products and their applications as green materials,” Foods, vol. vol. 10, p. p. 981, 2021.

[9] Instituto Nacional de Estatística, “Estatísticas da Pesca – 2020,” Instituto Nacional de Estatística, I. P., Lisboa, 2021.

[10] V. Vasconcelos, J. Moreira-Silva, S. Moreira, “Blue Bioeconomy Roadmap for Portugal,” BLUEandGREEN. CIIMAR,, Matosinhos, 2019.

[11] Bio Based Industries Consortium (BIC), “Mapping Portugal’s bio-based potential: Country Report,” Belgium, 2020.

[12] Monica Veronesi Burch, Arthur Rigaud; Thomas Binet & Clara Barthélemy, Vertigo Lab., “Circular economy in fisheries and aquaculture areas,” DevNet geie (AEIDL/Grupo Alba)/Kaligram., Brussels, 2019.